Feasibility Study: California Wool Mill

California Wool Mill Feasibility Study

The Challenge

As lead author, Warm Springs Consulting Principal, Amber Bieg, worked with Fibershed to produce a feasibility study to assess the technical, environmental, and economic feasibility of a vertically integrated wool textile mill in Northern California that could process up to five million pounds of California raw wool annually.

The Solution

The Solution

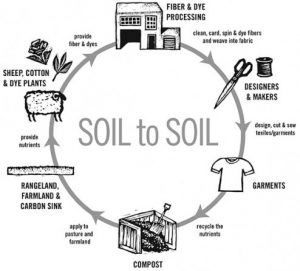

Amber’s team agreed that if California were to build a wool mill, this would have to be a very unique manufacturing facility – one that serves as a model for what textile manufacturing could be. This facility would account for the entire life cycle of a garment and support the betterment of local economies. This manufacturing plant would operate in a closed loop soil-to-soil system, where all the social, economic, and environmental impacts from the raw materials to processing and waste are accounted for and integrated into the environmental performance.

The team envisioned a vertically integrated, community-owned textile and garment production system. A system where the ranchers, designers, mill workers, and garment workers are not only treated in an ethical way, but are also owners and key stakeholders in this system. This would be a multi-stakeholder coop, much like the Food Commons model.

The Rudolf Steiner Foundation, Blackie Foundation, the Sarah and Evan Williams Foundation, and the Clara Fund generously supported this endeavor.

The feasibility study is broken into five main sections with goals specific to each section:

- Wool Inventory and Supply Analysis

- Demand Analysis

- Operations and Site Feasibility

- Financial and Environmental Performance

- Economic and Social Impact

1. Wool Inventory and Supply Analysis goal was to inventory and analyze the quantity and quality of California wool for fabric production. The target objective was to complete the first ever supply analysis of California wool and inventory at least five percent of the California wool supply. The Study Team directly inventoried 1.408 million pounds of raw fiber (44.8 percent of the California wool supply) for its quality (micron count) and quantity (pounds of wool per year). Then the Study Team worked with industry experts to determine the optimal uses of California fiber, dividing end use by quality (micron count).

2. Demand Analysis goal was to calculate the demand for California wool mill products and determine the optimal pricing. The target objective was to conduct interviews with at least ten California brands that would be interested in using California produced fabric as part of their supply chain. The Study Team conducted interviews with 12 brands that collectively purchase 85 million yards annually, with a total value of $409 million. Other information to support the demand analysis is macro-market research and consumer trends data.

3. Operations and Site Feasibility goal was to build a techno-economic model to determine the potential scale and scope of a ‘soil to soil’ fabric processing system based upon the California wool supply. The target objective was to create a systems-based design for the California mill; where one part supports the next in a closed loop system and the end of life for Fibershed fabric becomes the compost, fertilizing the rangelands, producing better grass and thus better wool. Like an ecosystem, every part is mutually supportive. Sourcing data and technical specifications from consultants and engineers, the Study Team has built an economic model that integrates engineering specifications and various scenarios for a closed-loop fabric manufacturing process. To better understand these systems and do the research for this model, Amber’s team traveled to North and South Carolina in June of 2013, engaging engineers and representatives from the wool industry. Over the next six months, working closely with Schlumberger, milling equipment manufacturer, waste water engineers, renewable energy experts, and soil scientists, the team built an integrated technical-economic model that reflects a highly interconnected system optimized for environmental and financial performance.

3. Operations and Site Feasibility goal was to build a techno-economic model to determine the potential scale and scope of a ‘soil to soil’ fabric processing system based upon the California wool supply. The target objective was to create a systems-based design for the California mill; where one part supports the next in a closed loop system and the end of life for Fibershed fabric becomes the compost, fertilizing the rangelands, producing better grass and thus better wool. Like an ecosystem, every part is mutually supportive. Sourcing data and technical specifications from consultants and engineers, the Study Team has built an economic model that integrates engineering specifications and various scenarios for a closed-loop fabric manufacturing process. To better understand these systems and do the research for this model, Amber’s team traveled to North and South Carolina in June of 2013, engaging engineers and representatives from the wool industry. Over the next six months, working closely with Schlumberger, milling equipment manufacturer, waste water engineers, renewable energy experts, and soil scientists, the team built an integrated technical-economic model that reflects a highly interconnected system optimized for environmental and financial performance.

4. Financial and Environmental Performance goal was to analyze various scenarios based on the integrated economic model and propose a scenario that optimizes both financial and environmental performance of the mill. The Study Team analyzed four scenarios comparing location of the mill as the only variable. All other variables were set as conservative assumptions, based on research for what the most probable scenario would be.

5. Economic and Community Impact goal was to quantify the macro Economic and Social Impact of the mill on the community where the mill will be situated. This impact analysis used existing research on economic multipliers and metrics for quantifying social impacts as well. This impact analysis is predictive and only gives an estimate based on the optimal scenario specified by the environmental and financial performance.